Automotive Wiring Standards Organizations

The automotive industry has long relied on a set of standards to ensure the safety and reliability of vehicles. Among the most important are automotive wiring standards—governing the wiring used in cars, trucks, and other vehicles.

Automotive wiring standards help manufacturers ensure that wires are properly rated for their intended use and compatible with other vehicle components. These standards also help engineers ensure the automotive wiring is routed safely and efficiently.

The Society of Automotive Engineers (SAE) is the leading organization responsible for developing the universally accepted automotive wiring standards. Automotive manufacturers worldwide use these SAE standards, and they play a vital role in ensuring the safety and reliability of vehicles.

Why Are Standards So Crucial for the Automotive Industry?

To state a bit of the obvious, standards are crucial for manufacturers because they ensure that products work reliably and safely. When working with complex electrical components, there's a high risk of overheating, electrocution, fire, and damage to surrounding parts. Therefore, it's critical that standards exist for consistency and quality.

As engineering and manufacturing have evolved over the years, the engineering standards library has expanded to include new technologies and innovations. Many standard-setting organizations also look at the manufacturing quality, the parts' environmental impact, and questions of ethics in sourcing and labor.

Standards also help manufacturers work with parts from different vendors and ensure that these parts all meet the criteria and work compatibility. If each company created its own parts without uniformity, the end product would be unpredictable and unreliable at best. It’s also crucial that many of the industry standards apply internationally, particularly with today’s global market, supply chain, and sourcing. All components must meet certifications and safety standards.

Manufacturers test their components and parts rigorously and carefully document that they meet the given standards. Some components are also certified by outside independent agencies, review boards, or associations, offering another layer of assuredness for a quality product.

Understanding the SAE vs. UL vs. ISO Standards

Three main organizational bodies set the standards in engineering: Society of Automotive Engineers (SAE), Underwriters Laboratories (UL), and the International Organization for Standardization (ISO). While the SAE is the predominant standards-bearer for the automotive industry, it's essential to become familiar with all three standards, as they’re used throughout the automotive industry and engineering.

SAE (Society of Automotive Engineers)

For over a century, SAE has focused on helping to standardize the automotive manufacturing process to improve safety and efficiency. Founded in New York in 1905, the organization has expanded its reach to become the leading global organization that covers far more than automobiles.

While SAE standards cover a wide range of components, at IEWC, we're most concerned with the standards governing electronics. SAE automotive wiring standards cover the high and low-voltage wire and cable, as well as connectors, plugs, and outlets. From the battery to taillights, SAE standards help manufacturers ensure that electronic components are properly rated for the task.

We encounter many common SAE wiring standards in the automotive industry. A few include:

- SAE J1171 covering marine ignition protection

- SAE J1127 covering battery cable specifications

- SAE J1128 covering low voltage primary cable

You can find the IEWC UL, Metric & SAE Strand Charts here.

UL (Underwriters Laboratories)

UL began as the Underwriters' Electrical Bureau—a group of National Board of Fire Insurance Underwriters members. The organization focuses on many aspects of safety and certification. They are approved by OSHA to perform safety testing, and many of their standards apply well beyond automotive industry standards.

UL standards most commonly apply to electrical components, materials, and systems. However, the organization also focuses on sustainability, food and water products, recycling, and other technologies such as renewable energy.

For electrical components in the automotive industry, common UL standards include:

- UL 4 Armored cable

- UL 13 Power limited circuit cable

- UL 44 Rubber-insulated wire and cable

- UL 62 Flexible cord and fixture wire

- UL 83 Thermoplastic-insulated wire and cable

- UL 1063 Machine-tool wires and cables

- UL 1072 Medium voltage power cables

- UL 1277 Electrical power and control tray cables w/ optional optical fiber members

- UL 1424 Power limited fire-protective signaling-circuit cable

- UL 1569 Metal clad cables

- UL 1581 Reference standard for electrical wires, cables, and flexible cords

ISO (International Organization for Standardization)

The International Organization for Standardization is composed of representatives from many standards organizations in the participating countries. The organization was founded in the late 1940s and is headquartered in Geneva, Switzerland. With 167 participating countries, the ISO works mainly in technical and non-technical fields outside of electronic engineering.

The ISO sets standards for quality, environmental sustainability, and other factors. Although the ISO sets the standards, product testing is performed by outside independent organizations. Like UL standards, the ISO focus is beyond the automotive industry, but there are certainly some areas of overlap.

A few ISO standards that we may find in the automotive industry are:

- ISO 9001 applies to quality business standards in companies and organizations

- ISO 8846 covers small craft electrical devices and components

Other Industry Standards

Other organizations have their own specific standards. For example, Ford and Chrysler Group have company-specific performance standards and specifications that exceed SAE standards for heat resistance and other factors.

American Society for Testing Materials (ASTM) conducts testing and specifications for some components and materials used within the automotive industry. In addition, the RV Industry Association (RVIA) has its own additional standards for use with recreational vehicles.

Automotive Wire Testing & Certification Processes

Before automotive wiring components can be certified, they must undergo testing to ensure they meet the required standards. These tests are designed to simulate real-world conditions and stress the components to their limits. For example, wires are subjected to extreme temperature fluctuations, mechanical vibrations, and exposure to chemicals and moisture to assess their durability and performance.

Once wiring components have passed the necessary tests, they can receive certification labels from organizations like the UL. These labels indicate that the product meets or exceeds the relevant standards. For consumers and manufacturers, these certification labels provide confidence that the wiring components will perform safely and reliably.

Certified wiring components are essential for ensuring vehicle safety and compliance with regulatory standards. For manufacturers, using certified components reduces the risk of product recalls, legal issues, and damage to brand reputation. For consumers, certification provides assurance that the wiring in their vehicles meets high safety standards, contributing to overall vehicle reliability and performance.

At IEWC, we carefully ensure our automotive products meet the necessary standards and are of the highest quality. If you have any questions about the standards used or the products available, please reach out today to learn more.

Contact IEWC today to learn more!

Related Resources

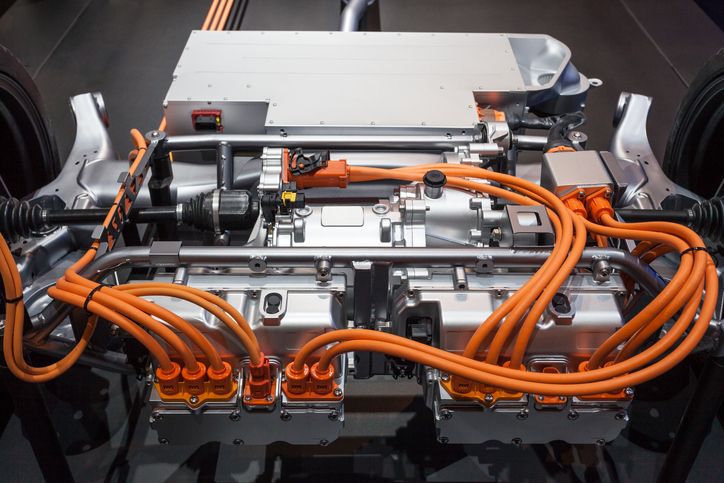

Electric Vehicle Wiring Specifications

As consumer demand continues to rise, so does the need for electric vehicle wire, cable, and other charging components.Learn More

Motor Lead Ratings

With electric motor performance and safety, the choice of insulation materials and wire temperature ratings is critical.Learn More

Industry Organizations & Standards

Understanding industry organizations and standards is essential for anyone involved in manufacturing, installation, or regulatory compliance.Read More