High Voltage Wire & Cable Guide

High-voltage or HV wire and cable are necessary for many industrial applications that rely on dependable high-power transmission. Whether you’re looking for the right HV cable for your application or trying to learn more about how HV wire and cable work, we’ll break it down for you.

High-voltage or HV wire and cable are necessary for many industrial applications that rely on dependable high-power transmission. Whether you’re looking for the right HV cable for your application or trying to learn more about how HV wire and cable work, we’ll break it down for you.

At IEWC, we know wire and cable. We’re here to help you find the right fit for any project or need. Reach out today if you need guidance on your high voltage wire or cable.

What is High Voltage (HV) Wire and Cable?

What is a high voltage cable? If you work in any power-related industry, you're probably at least somewhat familiar with HV wire and cable. HV wire and cable manage the transmission and distribution of electrical power above 1,000 volts AC (alternating current).

HV wire and cable are crucial for high voltage applications that need a lot of power—especially if that power needs to be transmitted over a significant distance with minimal energy loss. This level of high voltage is often found in the transmission of electrical power from plants to substations. It's also found in high-current industrial applications that require large amounts of power (e.g., heavy electrical equipment and large motors).

HV cables are made to stand up to high voltage and harsh environmental stress. They’re built to be reliable and safe, meeting the demands of some of the toughest jobs, including;

- EV Charging: In the EV industry, high voltage cable is used to transmit power from the battery to the motor, inverter, and charger, handling voltages from 200V to 800V; some even carry communication signals for vehicle monitoring and management.

- Wind and Solar Farms: HV cables are vital for transmitting the power generated by solar panels and wind turbines to the local grid or power collection system.

- Industrial Plants: HV wire is a critical tool for large industrial plants. HV cable helps supply power to large motors, heavy-duty machines, and high-power equipment.

- Mass Transit and Rail: HV cables power electric rail systems like light rail and subway trains, bringing reliable power to public transportation.

- Aerospace Applications: Many aerospace applications require this type of cable too. Hook-up wires and power supplies must offer excellent resistance and electrical performance.

- Mining: High voltage wires supply power over great distances and deep into underground mine operations to power excavators, drills, and conveyor belts.

Benefits of High-Voltage Wire and Cable

Why choose HV wire and cable? When you need high voltage, you need the cable built for the situation. Here are some key advantages of choosing high voltage cable for your application.

- Enhanced Power Transmission and Efficiency: When you need high-voltage transmission, HV cables are the answer. These durable cables safely transmit electrical power, even over long distances. Compared to lower voltage cable systems, there's much less energy loss in the transmission. The higher the voltage, the lower the current required for transmission, which lowers the rate of energy lost as heat from resistance.

- Lower Space and Material Requirements: Despite their powerful nature, high-voltage cables require thinner conductors (because they're built to carry more power). Because the cables are thinner, the space requirements and even the cost of materials for cable runs are lower. HV cables are made for tight tolerances.

- Durable and Long-Lasting: HV cables and wire are made for the toughest environments and harshest jobs. Thanks to their material composition, they can withstand extreme temperatures, UV exposure, life underground, chemicals, wet environments, and stress. High-voltage cable boasts a robust construction that is low-maintenance and long-term cost-effective.

- High Capacity: Because high-voltage cables can handle very large loads, they're the best choice for applications that require high power levels. For industrial machinery, public utilities, and power plants, HV wire and cable meet the demand, even at peak usage.

- Safe and Stable: HV cables are well-insulated. Their design and engineering use advanced technology to enhance safety. HV wires and cables prevent hazards like power surges and electrical arcs.

High Voltage Cable Design

High-voltage cables and wires can handle significant power loads because they've been designed for them. All of the components and engineering of these cables are done with the power demands in mind. Here are some of the most common materials used to create HV cables.

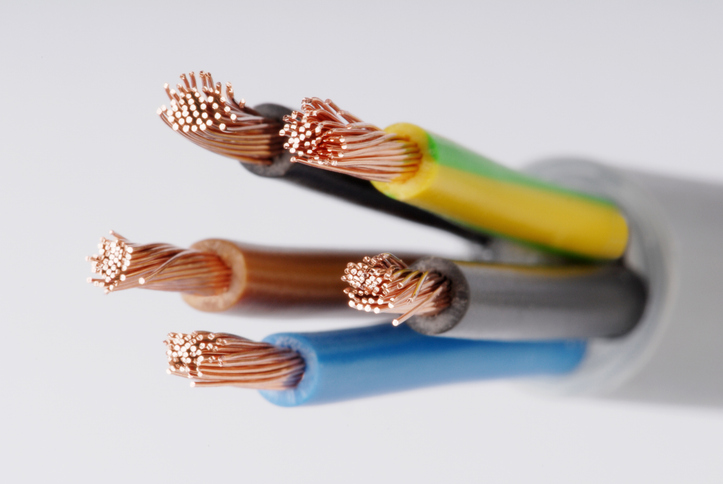

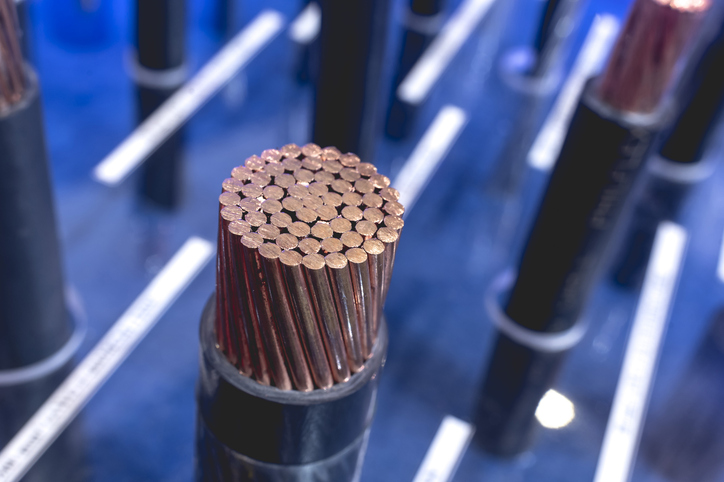

Conducting Materials

Every electrical wire and cable needs a conductor to transmit the power within. The most common materials used in HV cables are copper and aluminum. Most applications favor a copper conductor because stranded copper wire is very flexible and an excellent conductor. Aluminum is lighter weight and less costly, but it has a slightly lower conductivity.

Insulation Materials

Insulation protects the conductor within the cable and wire. XLPE (cross-linked polyethylene) is a common insulator choice for HV cable. It's an excellent insulator with temperature and chemical resistance. EPR (ethylene propylene rubber) is another popular option due to its high flexibility and electrical insulating properties. PVC (polyvinyl chloride) is a less common choice but is used for some HV applications because of its fire resistance and flexibility.

Sheathing Materials

Sheathing protects the HV cables from the outside. The sheeting materials help to ensure that cables can resist environmental factors. Polyethylene or PE is one of the more common versatile choices. PVC is another sheathing option that resists UV light, oil, and other chemicals. Metal sheathing is an option for cables that need extra protection (such as those buried underground or used underwater)—metal sheaths in lead or aluminum guard against moisture and other environmental damage.

Additional Components

Depending on the HV cable, additional components may also be used. Semiconducting layers between the conductor and insulation smooth the surface for a uniform field. This prevents the formation of voids that can cause insulation failure.

Armoring is often used for cables in high-mechanical-stress environments, such as underwater or underground. Armoring consists of steel wires or steel tape that protects the cables from damage.

Determine the HV cable components you need based on the requirements of your application and the targeted environmental conditions. If you're unsure of the correct cable needed, please reach out, and we can help you find a cable that works reliably and efficiently, even in challenging conditions.

High Voltage Wire and Cable Specifications

How do you decipher high-voltage cable and wire specifications? HV cable and wire are available in a wide variety of technical specifications, including gauge, voltage, temperature tolerances, and component materials. These specifications give you a good idea of how a cable will perform.

Gauge

HV cables feature a wide range of conductor sizes, measured in AWG (American Wire Guage) and, in some cases, square millimeters (mm²). The conductor size impacts the capacity and diameter of the cable. Most gauge sizes range between 2 AWG and 28 AWG. Smaller diameters are ideal for tighter tolerances.

Voltage

The voltage rating indicates the maximum voltage an HV cable can safely handle. High voltage cables commonly start at 1,000 volts (1 kV), with some options going up to 35 kV or higher for a maximum voltage rating. It's important to match the voltage rating to the system's operating voltage to protect the insulation and ensure safe use.

Temperature

The temperature range specifications will indicate the highest and lowest temperature that the cable components can safely tolerate. It's especially important to consider the temperature range for fluctuating environments. Many HV cables fall between -40°C to 90°C. When components like XLPE and EPR are used, they can support a broader range—75⁰C to +250⁰C. These wider temperature tolerances are ideal for environments with high thermal stress.

Materials

The specifications also indicate the conductor, insulation, and sheathing materials. The conductor materials are typically copper or aluminum. Insulation materials may be XLPE, PVC, or EPR. Sheathing and jackets are available in PE, PVC, and various types of metal.

Additional Specifications

Some cables may also include specifications regarding flexibility. More flexible cables often employ stranded conductors, pliable insulation, and sheathing materials. The HV cables may also have resistance specifications (e.g., oils, chemicals, UV light, and abrasives).

Find High Voltage Wire and Cable At IEWC

Whatever the application, from wind turbines to oil rigs to power utilities, HV cable can meet your needs. At IEWC, we carry an array of high voltage wires and cables for many power applications.

If you need assistance with choosing high-voltage wire or cable, reach out to request a quote. Our high-quality products are reliable, tough, and built to last. When you have high-voltage cables, safety and durability are paramount. At IEWC, you can always trust us to deliver.

Related Resources

Basic Ampacity Values

Ampacity, or current carrying capacity, is defined as the current a conductor can carry before its temperature rise exceeds a permissible value.Learn More

Stranding Classes

Wire stranding classes refer to the categorization of stranded wires based on their construction characteristics.Learn More

Metric Conversion Table

In selecting a wire or cable for an application, several factors should be considered including size and conversions. Learn More