Selecting Wire & Cable Solutions for HVAC

HVAC (heating, ventilation, and air conditioning) systems require reliable, durable, energy-efficient wiring solutions for smooth operation, safety, and compliance with industry regulations.

The right cable selection is essential for the performance and longevity of HVAC units (typically no small investment for a business). Fortunately, IEWC provides dependable quality wire and cable solutions for HVAC and building system applications. Here's what you should consider when choosing your cables and wire.

Understanding HVAC Cable Requirements

Under the umbrella of HVAC are different types of cable:

- Power distribution cable

- Control/communication cable

Depending on environmental factors and insulation needs, there may also be different requirements for the cable and wire.

Power Distribution Cables

These cables deliver power to HVAC components such as compressors, motors, and fan units, so they must be able to handle high voltage loads efficiently.

Heat-resistant insulation is often critical due to the cable's proximity to heating elements. UL-rated cables are required for safety compliance in most settings and situations.

If you need power distribution cables, explore the options of THHN/THWN wires and XHHW-2 wires for applications that need high-temperature resistance. Here are the details on these two types of HVAC Power Distribution Cables.

- THHN/THWN Wires: These wires are commonly used in HVAC power distribution and general electrical applications. They typically feature thermoplastic (PVC) insulation and a nylon jacket that makes them resistant to factors like heat, moisture, and oil. The THHN is rated for dry locations up to 90°C, and TWWN can be used in wet locations up to 75°C. These cables are cost-effective, widely available, and easy to work with.

- THHN stands for: thermoplastic, high-heat resistant, and nylon-coated.

- THNW stands for: thermoplastic, heat-resistant, nylon-coated, and water-resistant.

- XHHW-2 Wires: Are best suited for high-temperature and high-moisture environments, making them the ideal choice for HVAC applications in more extreme conditions. These wires are constructed of cross-linked polyethylene (XLPE) insulation for additional heat resistance and durability. The HVAC cables are rated for 90°C in both wet and dry environments. With superior insulation and moisture resistance, these cables meet the most demanding HVAC needs.

- XHHW-2 stands for: Cross-linked polyethylene (XLPE) insulation, high-heat resistant, water-resistant, rated -2 - 90°C for wet and dry conditions.

Control & Communication Cables

The other types of cables used in HVAC are control and communication cables. These cables do the job of connecting HVAC sensors, thermostats, and automation systems.

Control and communication cables need to have shielding to protect them against electromagnetic interference (EMI). Twisted-pair, or fiber optic cables, improve data integrity for smart HVAC systems.

For HVAC control and communication, explore PLTC/CL3 cables for lower voltage applications. Belden-shielded twisted-pair cables work well to reduce signal interference for smooth communication.

- PLTC/CL3 Cables: These cables are commonly used in low-voltage HVAC control operations like sensors, building automation systems, and thermostat wiring. The PLTC cables are rated for use in cable trays and control circuits and feature a flame-retardant jacket for protection. CL3 cable is rated for power-limited circuits up to 300V and is commonly used in HVAC alarms, controls, and security systems. Both types of cables are temperature rated for 75°C to 90°C. Choose from shielded and unshielded options, depending on the application. These indoor and outdoor cables are fire-resistant and meet the NEC requirements.

- PLTC stands for: power-limited tray cable.

- CL3 stands for: class 3 cable.

- Belden Shielded Twisted-Pair (STP) Cables: These cables are typically used to reduce signal interference. They’re ideal for HVAC communication, networking, and other industrial control applications. The cable includes a foil or braided shield to protect against EMI and radio frequency, or RFI interference. The twisted-pair design cancels out the noise to ensure a consistent signal transmission. The temperature rating can vary by cable type but generally meets the needs of industrial-grade environments. The cable is also available in plenum-rated versions for installation in air-handling spaces, commonly found in HVAC.

Environmental Factors & Insulation Requirements

All HVAC cables must be able to withstand extreme temperatures in both hot and cold environments. They need to resist humidity and moisture exposure, as well as mechanical stress from movement and vibration. These cables do a big job and are worth investing in top-of-the-line to protect your building.

Choose features like thermoplastic or thermoset insulation for extra durability. For outdoor HVAC installations, you'll need UV and weather-resistant jackets. Low-smoke, zero-halogen, or LSZH cables can offer extra safety for small, enclosed spaces.

Choosing the Right Cable for HVAC Efficiency & Compliance

When you're selecting an HVAC cable, what qualities should you look for, and what are the considerations to ensure you get the most efficient cables and wiring?

Look for energy-efficient options. The right cable will minimize energy loss and improve the performance of your HVAC equipment. If you are installing a smart HVAC system, you’ll need high-quality data cabling to support real-time monitoring and automation.

There are also industry standards to ensure regulatory and safety compliance. For HVAC, the standards include: UL 83 and UL 1277 for HVAC power cables, NFPA 70 / NEC compliance, and the ASHRAE standards for building energy efficiency.

Future-Proofing HVAC Systems with the Right Cabling

In today's world, with constantly changing technology, it's important to select the proper wires and cables for the safety, efficiency, and long-term reliability of your HVAC system. Consider the needs of your system today, as well as the future scaling and growth that may happen in your building.

To ensure you get the best cable and wire for your HVAC application, you should work with a reliable wire and cable supplier. IEWC is a leader in cable and wiring, with a vast range of solutions tailored for HVAC power, control, and communication.

If you have questions or need assistance with custom wire management solutions, reach out to our team. We can help you find the best option to optimize the efficiency and performance of your installation.

Related Resources

What is a Cable?

Cable, or cabling, consists of the twisting together of two or more insulated conductors.Learn More

How to Choose the Right Wire or Cable

In selecting a wire or cable for an application, several factors should be considered. Learn More

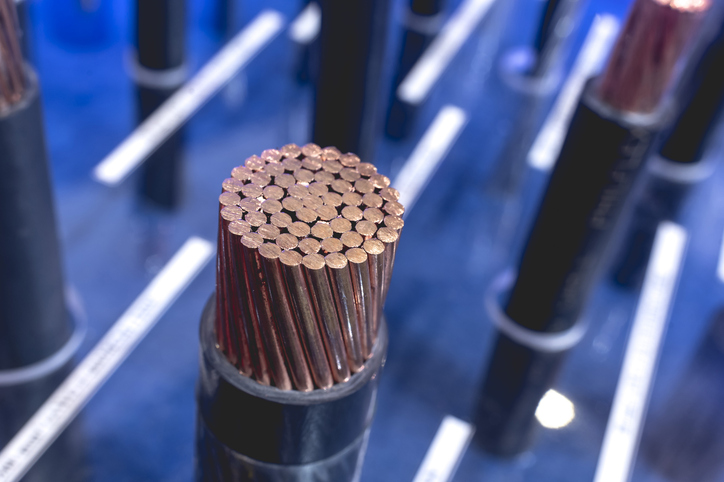

Selecting a Conductor

Even in the design of a simple single insulated wire many factors must be considered, including physical properties of the conductorLearn More