Types of Strand Construction

Understanding the Different Types of Strand Construction and Tinning in Electrical Conductors

When it comes to the design and functionality of electrical conductors, understanding the various types of strand construction and tinning processes is crucial. Each method offers unique characteristics that affect the performance and suitability of the conductor for specific applications. In this article, we’ll delve into the various types of strand construction, as well as the different tinning methods used in the industry.

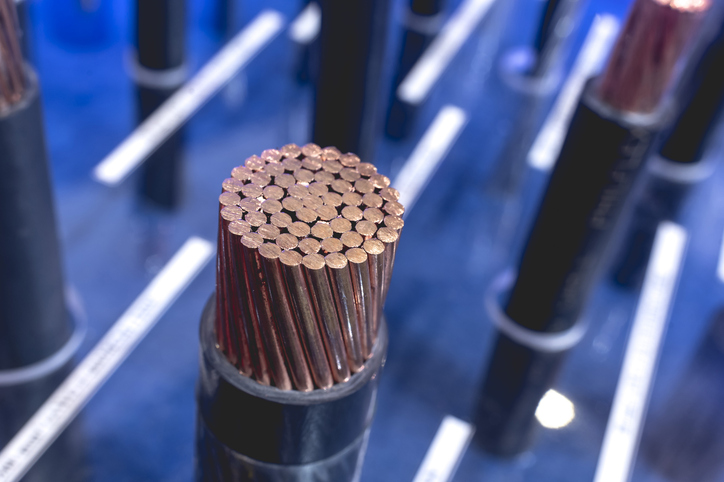

Types of Strand Construction

Strand construction plays a significant role in the performance of electrical conductors. Here’s a breakdown of the different types:

Bunched Stranding

Bunched stranding involves twisting together any number of strands in the same direction without considering their geometrical arrangement. This type of stranding is commonly used when flexibility is a key requirement. The standard direction for the lay is left-hand, which is typical in most stranding processes.

True Concentric Stranding

True concentric stranding consists of a central wire surrounded by one or more layers of wires. In this method, the direction of the lay is reversed with each successive layer, and the length of the lay increases with each additional layer. The outer layer typically has a left-hand lay, ensuring a balanced and stable construction.

Compressed Stranding

Compressed stranding refers to a conductor that is manufactured to a diameter no more than 3% smaller than that of a non-compressed conductor with the same cross-sectional area. This slight reduction in diameter allows for a more compact conductor without significantly affecting performance.

Unidirectional Concentric Stranding

Similar to true concentric stranding, unidirectional concentric stranding features layers of wires with the same direction of lay throughout. This consistency in lay direction, which is usually left-hand, provides a uniform and stable conductor structure.

Unilay Stranding

Unilay stranding mirrors true concentric stranding but with one key difference: the lay length remains consistent across all layers. The uniform lay length, combined with a left-hand direction, results in a conductor that is both reliable and efficient.

Equilay Stranding

Equilay stranding takes the concept of unilay stranding a step further by ensuring that both the lay length and lay direction are identical in each layer. This method, which typically employs a left-hand lay, produces a conductor with exceptional balance and consistency.

Rope Stranding

Rope stranding involves creating cabled groups from any of the aforementioned stranded members. This type of construction is often used when additional flexibility and strength are required, making it suitable for heavy-duty applications.

19-Wire Combination Unilay Conductors

This specialized conductor construction features 19 strands, starting with a central wire surrounded by an inner layer of six wires of the same diameter. The outer layer consists of six wires of the same diameter as the central wire, alternated with six smaller wires. The smaller wires have a diameter that is 0.732 times that of the central wire. All wires in both the inner and outer layers share the same lay length and direction, ensuring uniformity and performance.

Tinned Copper Conductors

Tinned copper conductors are commonly used in electrical and electronic equipment due to their enhanced soldering capabilities and resistance to corrosion. Although slightly more expensive than bare copper, the benefits of tinned copper often outweigh the additional cost.

Types of Tinning

There are several methods for tinning copper conductors, each offering distinct advantages:

Tinned Copper

This is the most basic form of tinning, where individual copper strands are tinned, making it the most cost-effective option. Tinned copper is widely accepted under various industry standards, including UL, CSA, ASTM, and MIL.

Heavy Tinned Copper

Heavy tinned copper is similar to standard tinned copper but features a significantly thicker tin coating. This type of tinning is often used with high-frequency induction heaters for bonding on stripped areas, while the rest of the wire retains its flexibility. It meets the same industry standards as regular tinned copper.

Prefused or Prebond Copper

Prefused or prebond copper consists of twisted strands of heavy tinned copper that are fused along their entire length by heating. While it shares characteristics with a solid conductor, it offers the advantage of flexibility without the risk of work-hardening and breaking, making it ideal for applications requiring frequent flexing. This type is accepted under UL and CSA standards but is generally not suitable for most MIL-W-16878 types.

Overcoated Copper

Overcoated copper is made by twisting tinned copper strands together and then applying an overall tin coating. It provides similar benefits as prefused copper, including enhanced flexibility and resistance to breakage. This type is accepted under UL and CSA standards but does not meet MIL specifications.

Topcoated Copper

Topcoated copper is similar to overcoated copper but uses bare copper strands instead. It offers the same advantages in terms of flexibility and durability, and is also accepted under UL and CSA standards, though not under MIL specifications.

Understanding Conductor Twist (Pitch)

The twist or "pitch" of a conductor refers to the length over which a strand makes a complete revolution around the axis of the conductor. Pitch can be either short or long, with each offering different advantages.

- Short Pitch: A conductor with a short pitch is less likely to flare out when cut, making it suitable for applications where precision is critical, such as automatic equipment that strips insulation and applies terminals in one operation.

- Long Pitch: Conversely, a conductor with a long pitch may flare more easily when cut but is still acceptable for most automated processes. The choice between short and long pitch depends on the specific requirements of the application.

Understanding the various types of strand construction and tinning methods is essential for selecting the right conductor for your application. Each method offers unique benefits, whether it's enhanced flexibility, durability, or resistance to corrosion. By choosing the appropriate construction and tinning process, you can ensure optimal performance and longevity of your electrical conductors.

Related Resources

How to Choose the Right Wire or Cable

In selecting a wire or cable for an application, several factors should be considered. Learn More

Selecting a Conductor

Even in the design of a simple single insulated wire many factors must be considered, including physical properties of the conductorLearn More

Stranding Classes

Strand construction in wire and cable is crucial because it directly affects flexibility, durability, and electrical performance, impacting the overall reliability and efficiency of the cable in various applications.Learn More