Armor

Understanding the Importance of Armored Cables in Industrial Applications

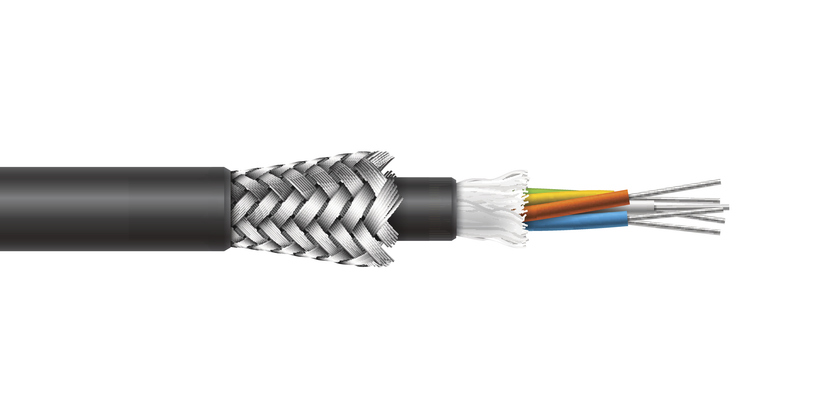

Armored cables are an essential component in industrial settings, providing critical mechanical protection and durability. These cables feature a helical winding of metal tape, typically made from copper, steel, or aluminum, that is placed over the outer sheath. This armor is designed to safeguard the internal conductors from physical damage, making armored cables a reliable choice for harsh environments.

What Are Armored Cables?

Armored cables are a self-contained conduit-wire system that offers enhanced protection and functionality. The metal sheath or armor that encases the cable serves not only as a barrier against impact and crushing but also as an effective electrical shield in many applications. This dual-purpose design ensures that armored cables are well-suited for a variety of industrial uses, including in pulp and paper mills, chemical and petroleum industries, and other demanding environments.

Key Applications of Armored Cables

Armored cables are versatile and can be used in a wide range of applications. They are commonly utilized in tray systems, direct burial, and in free air, both in wet and dry locations. The robust construction of these cables makes them ideal for power, instrumentation, and control applications across various industries.

Power Applications: Armored power cables are designed to handle voltage levels ranging from 600 volts to 35 kV. Most of these cables comply with the National Electrical Code (NEC) 310, ensuring safety and reliability in demanding settings.

Control Applications: Armored control cables are available with a large number of conductors, making them suitable for complex control systems. These cables are particularly beneficial in hazardous locations where additional protection is necessary.

Instrumentation Applications: Armored instrumentation cables can be customized to meet specific requirements, ranging from shielded pairs to coaxial cables. Many of these cables comply with NEC 725, making them ideal for precise instrumentation tasks in industrial environments.

Benefits of Using Armored Cables

The use of armored cables offers several key benefits that contribute to their widespread adoption in industrial settings:

- Enhanced Mechanical Protection:

The metallic armor provides robust protection against physical damage, such as crushing and impact, ensuring the longevity and reliability of the cables. - Electrical Shielding:

In addition to mechanical protection, the armor also serves as an effective electrical shield, reducing electromagnetic interference (EMI) and enhancing signal integrity in sensitive applications. - Versatility:

Armored cables can be used in a variety of environments, including underground, in tray systems, and in open air, making them a versatile solution for many industrial needs. - Safety Compliance:

Many armored cables meet stringent safety standards, such as NEC 310 and NEC 725, ensuring that they are suitable for use in hazardous and demanding environments.

Armored cables are a critical component in industrial applications, offering a combination of mechanical protection and electrical shielding. Their versatility and durability make them an excellent choice for a wide range of uses, from power distribution to complex control and instrumentation systems. By understanding the unique benefits and applications of armored cables, industries can make informed decisions to enhance the safety and efficiency of their operations.

Related Resources

Popular Armor Types

Two of the most common armor types are Interlocked Armor and Continuously Welded Corrugated Armor.Learn More

Shielding

Shielding is a vital aspect of cable design , providing a protective barrier that confines electrical energy within the cable. This shielding prevents signal leakage, which could lead to interference with nearby cables or sensitive electronics. It also safeguards the cable's signal from external sources of electromagnetic interference (EMI), ensuring the data remains intact and reliable.Learn More

What is a Cable?

Cable, or cabling, consists of the twisting together of two or more insulated conductors.Learn More