Popular Armor Types

Understanding Popular Armor Types for Cables

When it comes to protecting cables, choosing the right armor type is crucial. The two most common armor types are Interlocked Armor and Continuously Welded Corrugated Armor. Each type offers unique features and benefits, making them suitable for different applications. In this article, we will explore these armor types in detail, highlighting their construction, uses, and advantages.

Interlocked Armor: Flexible and Robust Protection

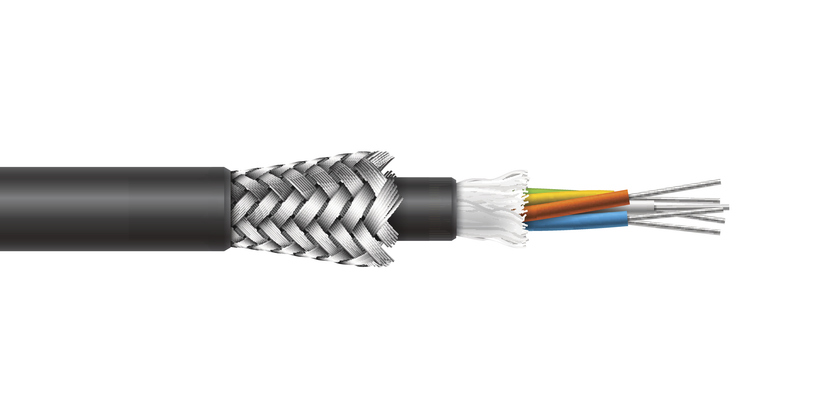

Interlocked Armor is a popular choice for cable protection due to its flexibility and robust design. This type of armor is constructed using steel or aluminum tape, which is spirally wound and formed around the cable. The unique interlocking design ensures that each layer is securely connected to the previous one, providing enhanced durability and flexibility.

One of the significant advantages of Interlocked Armor is its compliance with NEC Type MC (Metal Clad) standards, ensuring it meets the necessary safety and performance requirements. Additionally, a PVC jacket is often applied over the armor, offering extra protection against environmental factors.

Applications of Interlocked Armor:

- Direct Burial: Suitable for underground installations where additional protection against physical damage is required.

- Tray Installations: Ideal for use in cable trays, where flexibility and strength are essential.

- Free Air: Used in environments where cables are exposed to air, offering reliable protection without compromising flexibility.

Continuously Welded Corrugated Armor: Impervious and Durable

Continuously Welded Corrugated Armor is designed for applications where maximum protection against environmental factors is required. This armor type is constructed from aluminum tape that is formed longitudinally around the cable. The aluminum sheath is continuously welded as it is formed, creating an impervious barrier that prevents the ingress of water, gas, and corrosive elements.

The robust design of Continuously Welded Corrugated Armor makes it ideal for use in challenging environments, particularly in industries such as oil, gas, and paper. It is commonly used in AC drive power cables and complies with NEC Type MC-HL standards for use in Class 1, Division 1 hazardous locations.

Applications of Continuously Welded Corrugated Armor:

- AC Drive Power Cables: Provides essential protection for power cables in industrial environments.

- Hazardous Locations: Suitable for use in areas where explosive gases or dust are present, ensuring safe and reliable cable performance.

- Oil and Gas Industries: Extensively used in these industries due to its resistance to corrosive elements and harsh conditions.

Choosing the Right Armor Type for Your Needs

Selecting the appropriate armor type depends on the specific requirements of your application. Interlocked Armor is ideal for situations where flexibility and compliance with NEC Type MC standards are essential. It offers robust protection while allowing for easier installation in environments like cable trays and direct burial.

On the other hand, Continuously Welded Corrugated Armor is the preferred choice for environments where maximum protection against environmental hazards is needed. Its impervious design ensures that cables remain safe from water, gas, and corrosive substances, making it the go-to option for hazardous locations and industries like oil and gas.

Understanding the differences between Interlocked Armor and Continuously Welded Corrugated Armor is key to ensuring that your cables are adequately protected in various environments. By selecting the right armor type, you can enhance the durability and safety of your installations, whether they are in industrial settings, hazardous locations, or underground.

Both armor types have their distinct advantages, and choosing the right one will depend on your specific needs and application requirements. Ensure you consider the environment, safety standards, and installation conditions when making your decision. Contact IEWC to talk to a dedicated team member about the correct armor type for your specific application.

Related Resources

Armor

Armor refers to mechanical protection for cables; usually a helical winding of metal tape placed over the outer sheath.Learn More

Shielding

Shielding is a vital aspect of cable design , providing a protective barrier that confines electrical energy within the cable. This shielding prevents signal leakage, which could lead to interference with nearby cables or sensitive electronics. It also safeguards the cable's signal from external sources of electromagnetic interference (EMI), ensuring the data remains intact and reliable.Learn More

What is a Cable?

Cable, or cabling, consists of the twisting together of two or more insulated conductors.Learn More