Cable Sleeving for Wire Management

Cable sleeving is the process of encasing wires in a durable and versatile protective covering. This guide explores everything you need to know about cable sleeving, from selecting the right materials to understanding its applications.

The Key Benefits of Cable Sleeving:

- Enhanced Protection: Provides a reliable shield against physical damage, chemical exposure, and extreme temperature conditions, ensuring the longevity of cables.

- Streamlined Organization: Helps bundle and manage multiple cables efficiently, reducing clutter and making maintenance tasks more straightforward.

- Polished Appearance: Delivers a tidy and professional aesthetic, elevating the overall presentation of cable installations.

- Increased Safety: Reduces hazards caused by exposed or tangled wires, promoting a safer and more secure environment.

Selecting the Right Cable Sleeving

Choosing the correct cable sleeving for your application involves considering several factors to ensure performance and longevity. Here’s what to look for:

- Material Composition: Different materials offer varying levels of flexibility, durability, and resistance to environmental factors:

- PET (Polyethylene Terephthalate): This material is lightweight, flexible, and resistant to abrasion and chemicals.

- Nylon: This sleeving offers high tensile strength and excellent abrasion resistance.

- Fiberglass: Provides superior heat resistance, suitable for high-temperature applications.

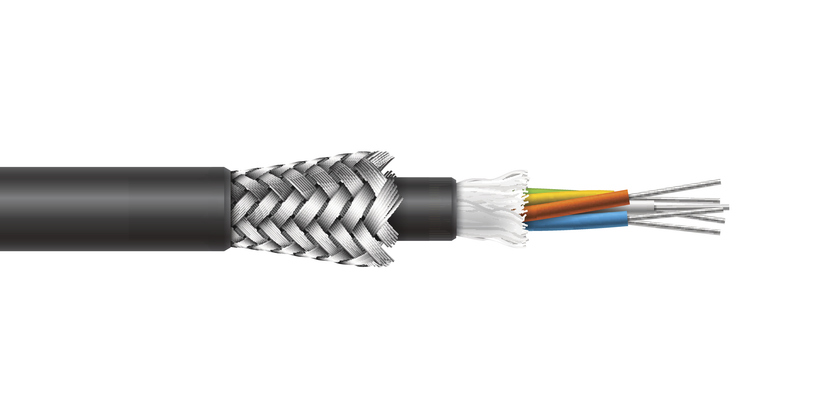

- Steel or Tinned Copper: This is extremely durable and resistant to physical wear. Can withstand high-temperature or harsh environmental conditions, including abrasion, impact, and corrosion.

- Temperature Resistance: Ensure the sleeving can withstand the operating temperatures of the environment.

- Flexibility: Depending on the application, the sleeving should offer the necessary bendability without compromising integrity.

IEWC offers a wide range of sleeving types to meet diverse requirements:

- Expandable Sleeving: Made from materials like PET (polyethylene terephthalate), this sleeving can expand to accommodate various cable sizes and contracts for a snug fit. It is flexible, lightweight, and resistant to abrasion and chemicals as well as ideal for bundling cables of different diameters.

- Non-expandable Sleeving: Maintains a fixed diameter, providing consistent protection. It is best for cables with uniform sizes where expansion isn't necessary.

- Coated Sleeving: Features coatings like silicone or PVC to enhance resistance against specific environmental factors. It is used in settings requiring extra protection against moisture or chemicals.

- Metal & Shielding: Metal-based sleeving, such as those made from stainless steel or tinned copper, offers shielding against electromagnetic and radio frequency interference. It provides robust protection in harsh environments.

- Wrappable Sleeving: Designed with a slit for easy application without disconnecting cables. Suitable for environments where cables are frequently added or removed, such as data centers.

Industries like automotive, aerospace and defense, industrial automation, and telecommunications rely on cable sleeving to bundle and protect critical cables. Whether you need expandable sleeving for versatile sizing, non-expandable or coated options for enhanced durability, metal shielding to block interference, or wrappable designs for easy modifications, there’s a solution to meet your specific requirements. If you have questions about the capacity of any wire management product, don't hesitate to contact our team at IEWC.

Alternatives to Cable Sleeving

Businesses often require specialized solutions for cable management to meet industry-specific demands, optimize efficiency, and maintain safety standards. While cable sleeving is a popular choice, these alternatives also cater to needs in a variety of environments:

- Heat Shrink Tubing: Heat shrink tubing is one of the most common alternatives to cable sleeving. This type of tubing is essential for insulating and protecting electrical wiring from abrasion and environmental hazards. When heat is applied, the tubing contracts to form a snug, secure fit around the wire, effectively sealing out moisture, dust, and other contaminants.

- Spiral Wraps: Spiral wraps are a flexible protective sheathing suitable for standard operating conditions. The coiled design allows for easy application and removal, making it an excellent choice for setups that may require frequent adjustments. Additionally, its design ensures durability even with repeated flexing.

- Cable Ties: Cable ties, also known as zip ties, are a versatile and cost-effective solution for cable management. Available in various sizes and materials, they meet the needs of nearly every industry. With a simple yet effective locking mechanism, cable ties allow users to quickly bundle cables together, ensuring a clean and organized setup. Their affordability and accessibility make them a practical alternative to sleeving in many scenarios.

- Conduits: Conduits provide a sealed system for comprehensive protection against dirt, water, and other harmful substances. Available in materials such as metal and plastic, conduits can be tailored to specific environments. Additionally, they come in both rigid and flexible forms to accommodate varying external impacts, offering unmatched adaptability for industrial and commercial installations.

Find Cable Sleeving at IEWC

Cable sleeving is a simple yet transformative solution for managing wires and cables. Whether you’re tidying up your workspace or fortifying industrial setups, sleeving offers unparalleled benefits.

Explore IEWC’s extensive range of cable sleeving today and find the perfect fit for your needs. A variety of vendors including Techflex, Heyco, and Panduit provide products from heavy-duty solutions to reusable options to elevate your wire and cable management.

Related Resources

Automotive Wire Management

Whenever you’re securing wire for automotive use, it’s important to use cable management solutions such as sleeves, tubing, and ties. Read More

Cable Ties for Wire Management

Cable ties, also known as zip ties, are fastening devices designed to bundle and secure wires, cables, or other items. They come in a variety of materials, sizes, and designs, making them suitable for industrial, commercial, and residential use.Learn More

Wire Management in Industrial Automation

This guide will delve into the essentials of wire management in industrial automation , covering types of cables, wire management tools, best practices, and the importance of organized cabling for overall system performance.Learn More