Wire Management in Industrial Automation

In the fast-paced world of industrial automation, where precision, safety, and efficiency are paramount, effective wire management is a foundational aspect that often goes overlooked. Cables and wires serve as the lifeblood of automated systems, carrying power, data, and control signals across machinery and devices. Without a well-structured wire management system, these connections can become disorganized, leading to safety hazards, increased downtime, and operational inefficiencies. This guide will delve into the essentials of wire management in industrial automation, covering types of cables, wire management tools, best practices, and the importance of organized cabling for overall system performance.

The Importance of Industrial Wire Management

- Enhancing Safety: A well-organized wire management system minimizes the risk of electrical hazards like short circuits, shocks, and fires. Properly routed and secured cables prevent tripping and protect workers, ultimately contributing to a safer work environment.

- Improving Operational Efficiency: In industrial automation, poorly managed cables can lead to interruptions in power or data transfer, affecting machinery performance. Organized cabling allows for easier troubleshooting, maintenance, and ensures that machines run smoothly without interference or downtime.

- Extending Equipment Lifespan: Excessive bending, stretching, or abrasion of cables can lead to damage over time. Proper wire management reduces wear and tear, prolonging the lifespan of both cables and the equipment they connect.

- Facilitating Compliance with Standards: Adhering to industry standards and regulations is crucial in industrial settings. Proper wire management helps ensure compliance with electrical codes and safety standards, reducing the risk of legal issues and fines.

- Supporting Scalability and Future Upgrades: As industrial operations grow and evolve, the ability to easily add or modify wiring becomes essential. A structured wire management system allows for seamless integration of new equipment and technologies, supporting scalability and future upgrades without extensive rework.

Common Wire Management Tools and Accessories

- Cable Trays: Cable trays provide a structured path for cables, keeping them organized and secure. They are commonly used in large installations where multiple cables need to be routed along similar paths. IEWC offers a variety of Industrial Automation cables that are used within cable trays.

- Cable Ties and Wraps: Cable ties and wraps, such as those provided by HellermannTyton, are simple tools for bundling cables together, reducing clutter, and making maintenance easier.

- Wire Ducts: Wire ducts, provided by HellermannTyton and Panduit, protect cables from abrasion and external damage. They are especially useful in areas with high foot traffic or machinery movement.

- Sleeving: Sleeving, including products from Techflex, provides additional protection for cables against abrasion and external damage, making them ideal for environments with high foot traffic or machinery movement.

- Cord Grips: Cord grips secure cables at their entry or exit points, preventing them from being pulled out or damaged.

- Spiral Wrap: Spiral wrap bundles multiple cables together while allowing flexibility for individual cables to exit as needed, offering protection against abrasion and easy reconfiguration in dynamic environments.

Sustainable and Efficient Wire Management: Reducing Downtime and Embracing Eco-Friendly Solutions in Industrial Automation

Discover how optimized wire management not only improves maintenance efficiency and reduces downtime but also supports sustainability through eco-friendly cable choices. By combining organized cabling practices with environmentally conscious materials, companies can achieve smoother operations and reduce their ecological footprint.

Optimizing Wire Management for Maintenance and Downtime Reduction

Organized wiring makes it easier to perform maintenance tasks without interrupting operations. Accessibility is key; cables should be easily reachable for inspection and replacement. Proper labeling and routing of wires ensure quick identification and troubleshooting, minimizing operational disruptions.

Eco-Friendly and Sustainable Wire Solutions in Industrial Automation

Many companies are now opting for eco-friendly cables, such as Ecogen cables, which are designed with sustainability in mind. These cables offer the same durability and efficiency while reducing environmental impact. By choosing sustainable wire options, businesses can contribute to a greener future while maintaining high performance standards.

Elevating Industrial System Performance: Smart Cable Management Solutions for Today and Tomorrow

Effective wire management is essential for reducing signal loss, interference, and electrical resistance in high-performance industrial systems. Learn how to select the right cable management solutions tailored to your environment, including advanced options for dynamic setups like robotic arms. Stay ahead with insights into future trends and smart innovations in wire management that enable real-time monitoring and enhance system reliability and efficiency.

Selecting the Right Solutions for Your Needs

Consider factors like environmental conditions, wire type, and flexibility requirements when choosing trays, ties, and wraps. Proper selection ensures durability and efficiency in various industrial settings.

Advanced Solutions for Dynamic Environments

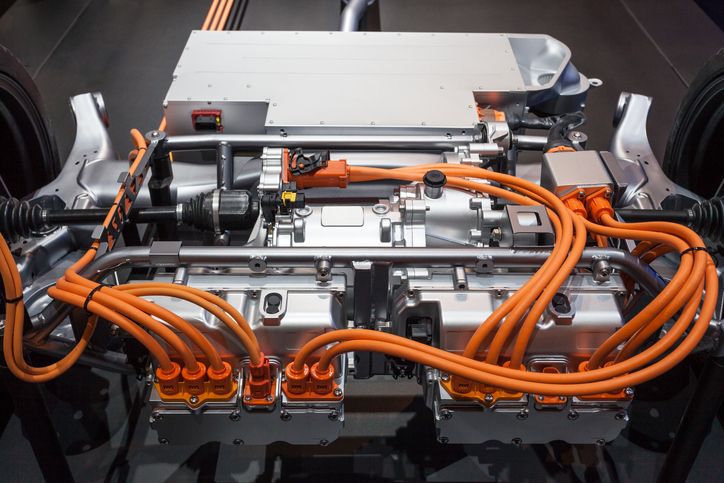

For setups with constant movement, like robotic arms, use flexible wires and secure them to minimize wear. These solutions help maintain performance and extend the lifespan of both wires and equipment.

Future Trends for Industrial Automation

Innovations in materials, designs, and smart wire management systems are making it easier to monitor and manage wires in real time. These advancements enhance system reliability and efficiency, preparing industries for future challenges.

Find Industrial Automation & Wire Management Products at IEWC

Effective cable and wire management is essential for maintaining safety, efficiency, and reliability in industrial automation systems. By choosing the right cables and tools and following best practices, companies can reduce downtime, enhance performance, and extend the life of their equipment.

IEWC's continued commitment to OEMs is evident in our extensive selection of industrial automation and control cables. If you're looking for a cable flexible enough for easy routing or one that can withstand repetitive movements and abrasion, while also withstanding harsh environmental conditions, IEWC has something to meet your needs from the world's best manufacturers. Buying wire management products from IEWC also allows you to have local stock, combine orders and shipments with wire and cable and consolidate your supplier base.

Related Resources

Tray Cable

Across industry, tray cable (type TC) is a go-to solution that works in some of the harshest indoor and outdoor environments. Tray cable is a strong cable option, with many different features that make it ideally suited for an array of applications. Learn More

High Voltage Wire & Cable Guide

High-voltage or HV wire and cable are necessary for many industrial applications that rely on dependable high-power transmission. Whether you’re looking for the right HV cable for your application or trying to learn more about how HV wire and cable work, we’ll break it down for you.Learn More

Application & Selection Guide for Standard Product

Read more on the typical applications for standard wire and cable products.Read More